Feed Grains for Beef Cattle: New Web Page

Feed grains, such as corn, barley, oats, and wheat, are important for Canadian beef production. Cereals are used as forage, including silage, swath grazing, or baled green feed, however cereal grains are a particularly attractive energy and protein source for the feedlot sector because of their high nutritional value, competitive pricing, and ready supply.

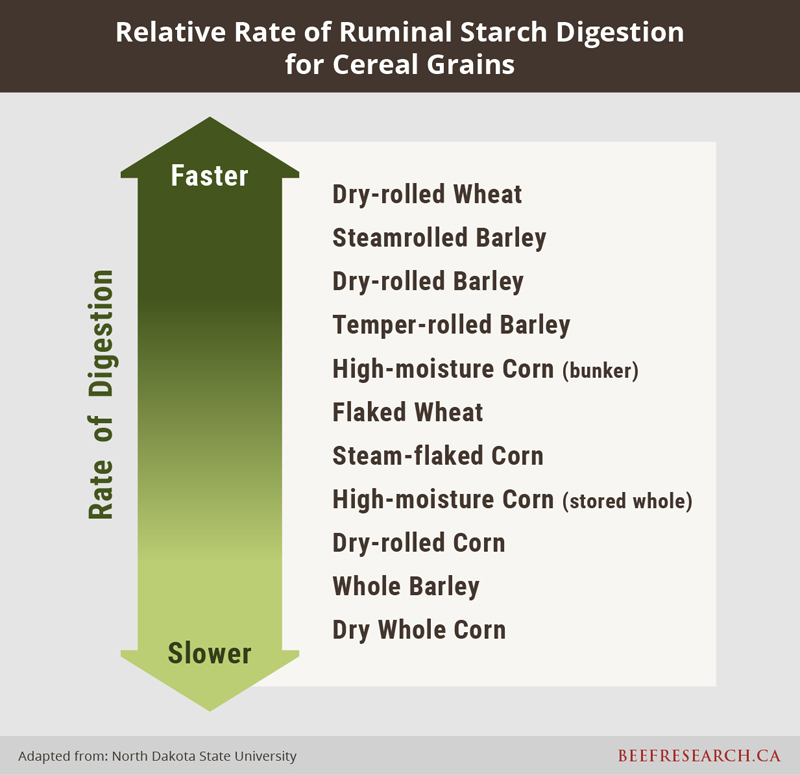

Corn is the most energy dense cereal grain, followed by wheat, then barley and finally oats. However, the energy (i.e. starch) in corn isn’t as digestible in the rumen or small intestine, whereas energy from wheat, barley and oat kernels are rapidly broken down to be used by the animal.

In terms of crude protein, wheat typically has the most protein followed by barley and oat, and then corn. Again, protein from wheat, barley or oats is more readily available for protein synthesis by rumen bacteria. Corn has a higher proportion of rumen undegradable protein, which means the protein “bypasses” the rumen and is only potentially available for digestion in the small intestine.

Grain may be processed to break open the hull or seed coat to allow the rumen bacteria to better access and digest the interior of the kernel. Because different cereals have varying kernel structure and nutritional properties, some cereals require additional processing to enable cattle to make the most of the nutrients available, while others may not. For example, oat and barley grains have an outer hull with a high fibre content. Oats can be fed whole because cattle, particularly animals less than a year old, can effectively chew the oat kernel and break through the hull. Barley, however, has a hull that is not broken down easily and acts as a barrier, reducing the ability of rumen bacteria to digest the grain. For that reason, barley benefits from being processed prior to feeding. Wheat does not have a hull but the seed coat is resistant to chewing and rumen fermentation and nutritionists recommend processing it to improve digestibility. Corn kernels are broken down fairly easily with chewing and rumen fermentation. Corn is a versatile grain and can be fed whole, dry rolled, steam flaked or as a high moisture grain.

It is very important to monitor grain processing to ensure particle size is appropriate. Under-processing can lead to poor digestibility and reduced feed value whereas over-processing can cause digestive upset or cause cattle to go off feed. The following methods are common ways to process cereal grains:

- Grinding cereals with a hammermill, adjusting particle size by using different screens;

- Dry-rolling grain using a roller mill that passes kernels through two rotating steel rollers, breaking kernels into two or three pieces;

- Steam-flaking by soaking grain in moisture (tempering) then subjecting it to steam which causes starch granules to absorb moisture and swell permanently, allowing better starch and protein digestibility;

- Steam rolling by steaming grain for a period of time then passing through a roller, resulting in a coarse, dense flake;

- High moisture grains are created by adding water to dry grains (tempering) or harvesting grain at elevated moisture levels. The high moisture grain is then further processing through a roller mill followed by ensiling in bunkers or bags.

Feedlot cattle can be fed high grain rations provided they are managed carefully. Step-up feeding programs include a series of carefully designed rations to allow cattle and their rumen bacteria to gradually adjust to the increased energy and minimize the risk of acidosis. For example, a starter ration may contain 30 to 40 per cent grain, 55 to 65 per cent forage, and 3 to 5 per cent supplement. As beef cattle move through the steps, the proportion of forage will decrease and grain will gradually increase until cattle reach the finishing ration which is comprised of 80 to 90 per cent grain, 7 to 15 per cent forage, and 3 to 5 per cent supplement.It can be a challenge to manage cattle on high grain rations. In addition to paying close attention to quality factors like moisture content, kernel plumpness, bushel weight, or the potential presence of mycotoxins, proper feed bunk management is important to ensure cattle remain healthy. Many feedlots keep cattle on full feed and manage bunks so that they are empty for a specified period of time (i.e. two to four hours) over the course of a 24-hour period. The following considerations can help producers reduce risks when feeding high grain rations:

- Provide multiple daily feedings;

- Use consistent feeding times;

- Recognize and adjust rations to mitigate weather-induced changes in feeding behaviour;

- Distribute feed evenly over the entire bunk;

- Consider providing an ionophore to minimize intake variation and control digestive upsets.

Feed grains present a valuable opportunity for feedlot operators and beef producers in Canada, however it takes management, knowledge, and experience when utilizing high-energy feeds. Learn more about optimizing the use of feed grains on the Feed Grains for Beef Cattle page.

Click here to subscribe to the BCRC Blog and receive email notifications when new content is posted.

The sharing or reprinting of BCRC Blog articles is welcome and encouraged. Please provide acknowledgement to the Beef Cattle Research Council, list the website address, www.BeefResearch.ca, and let us know you chose to share the article by emailing us at info@beefresearch.ca.

We welcome your questions, comments and suggestions. Contact us directly or generate public discussion by posting your thoughts below.